Steel molding: how it is done and what it is used for

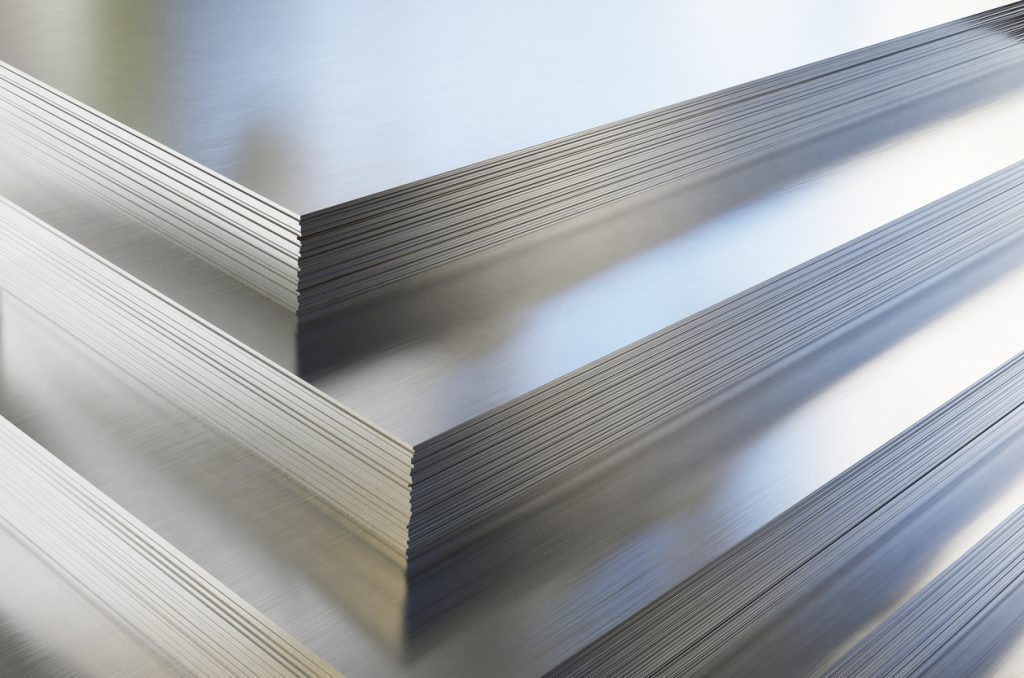

Deep drawing on stainless steel sheets is an advanced technique that has revolutionized many industrial sectors thanks to its unique characteristics and the possibility of obtaining shapes that are technically very complex. This technology is based on the use of powerful oleo-dynamic presses that work a stainless-steel sheet to create complex and three-dimensional components.

These components, obtained through the deep drawing process, are used in a variety of industries, helping to improve the quality, efficiency, and durability of the final products.

Stainless steel deep pressing: fields of application

For more than thirty years, Bravo Inox has specialized in deep stainless-steel pressing, that can be useful in many sectors:

- The catering and food preservation sector: through deep drawing and the following assembly and finishing processes, components widely used in the field of professional catering are obtained, such as stainless-steel tanks for fryers and pasta cookers, cooking tops, molded doors, mixers and planetary mixers, dishwasher bottoms, components for vacuum packaging machines

- In the medical, biomedical, and pharmaceutical industries, stainless steel is well-known for its resistance to corrosion and bacteria formation, making it an ideal material for ensuring safety and purity in medical processes. In this field, deep molding is typically used to obtain autoclaves for sterilization, laboratory incubators and centrifuges, and tanks for washing pans and other hospital objects.

- In many different industries, where deep drawing finds application for the fabrication of custom stainless steel components with fully customized shapes and features.

Hot forging and cold drawing of stainless steel

Stainless steel drawing can take place through two different processes: hot forging and cold forging. Both methods have their own peculiarities and advantages, which depend on the specific needs of the application and the required properties of the material.

Hot forging of stainless steel involves heating the metal to high temperatures, usually higher than its annealing temperature. This process makes the steel more malleable and easily machined, allowing the formation of complex, large workpieces with minimal resistance to deformation. However, it requires specialized equipment and consumes more energy than cold forging.

On the other hand, cold drawing takes place at room temperatures or slightly higher, without the need to heat the stainless steel. This process is generally cheaper, also in terms of energy consumption, than hot forging. In addition, it produces parts with more precise dimensional tolerances and a better surface finish.