Deep drawing of stainless steel

The processing of stainless steel through deep drawing is an advanced and versatile technique in the production of metal components. This process, also known as cold forming or cold stamping, allows the creation of complex, high-precision parts using metal plates without the use of heat.

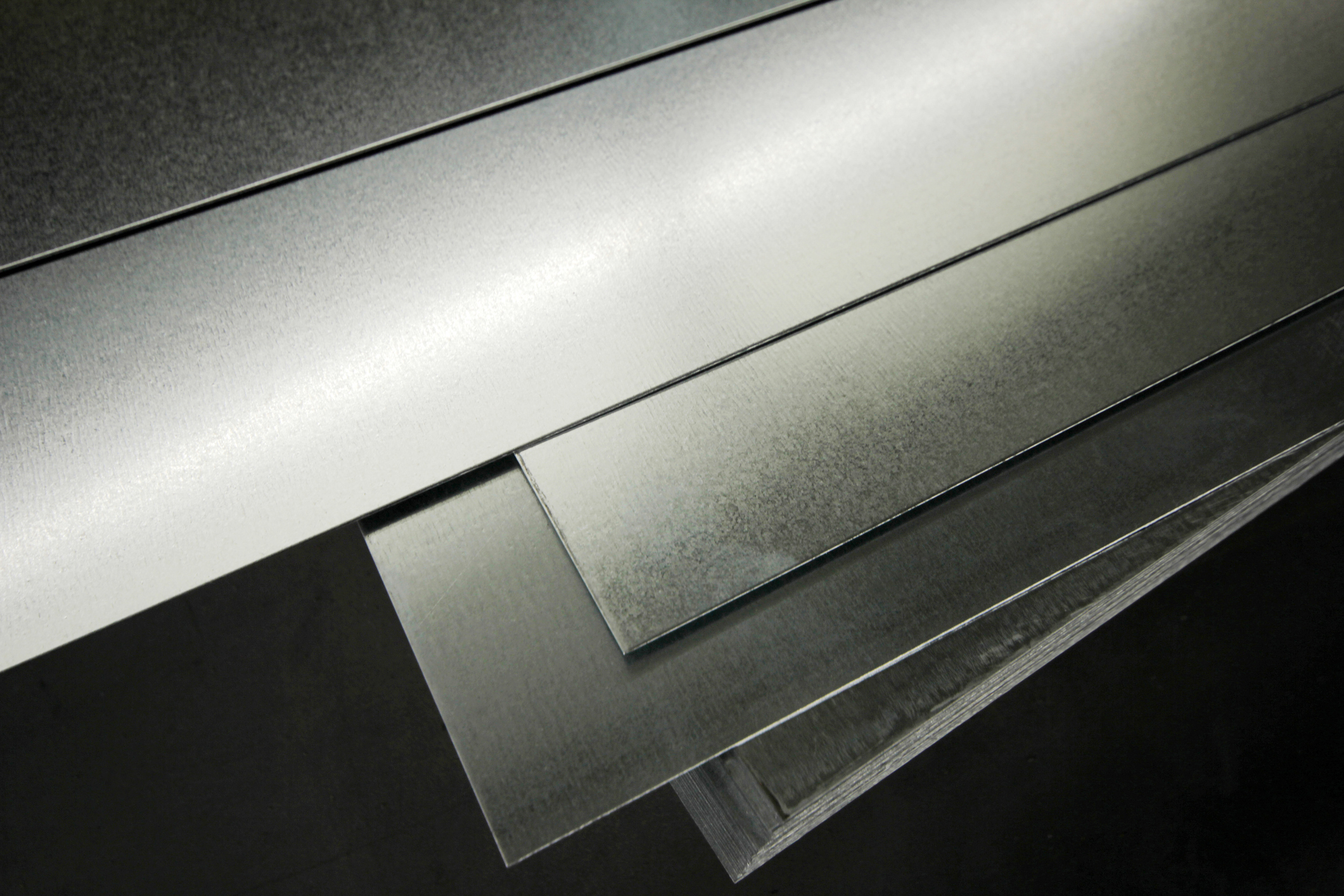

Stainless steel: the perfect material

The choice of material is a crucial activity in the drawing process of stainless-steel sheet metal. Its corrosion resistance, strength, and ability to maintain its mechanical properties even at extreme temperatures, make it the ideal material for deep drawing. The use of proper stainless steel alloys guarantees resistance to environmental conditions and the preservation of its characteristics over time.

How the deep drawing process of steel works

In the deep drawing process, stainless steel sheets are cut according to the final product specifications. After that, the sheet metal is placed into an oleo-dynamic press that applies considerable force on the surface of the material, pushing it through a mold to obtain the desired shape. The press applies a progressive force, gradually deforming the stainless-steel plate into the desired part. Shaping takes place at room temperature, without the aid of heat.

Based on the technical complexity of the desired final shape, the semi-finished product undergoes one or more forming operations, possibly interspersed with tempering in the annealing furnace. This thermal process is used to improve mechanical properties and reduce any residual stresses generated during cold working.